Product Application

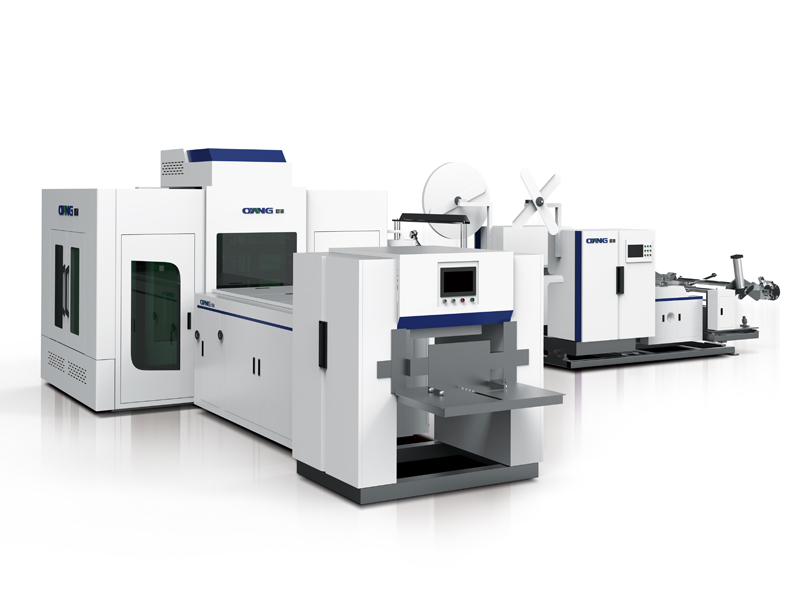

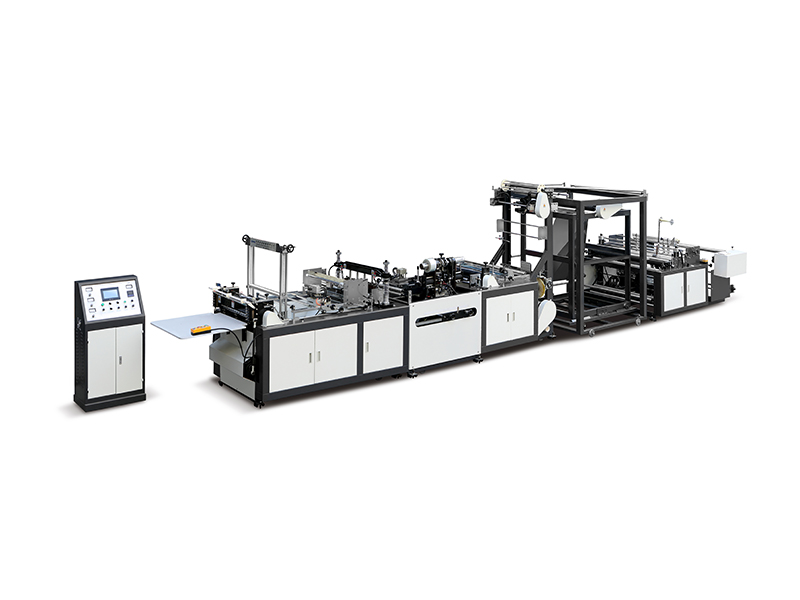

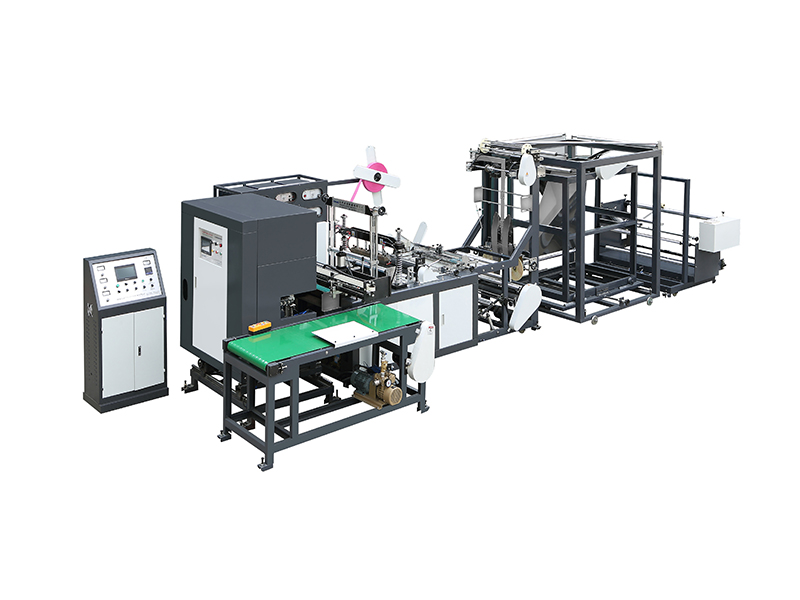

Leader-10S One Time Forming Non Woven Box Bag Making Machine is suitable for Laminated PP non woven fabric, Non-laminated PP non woven fabric, Aluminum film non woven fabric, Glitter film non woven fabric, Laser film non woven fabric,etc. It using non woven fabric roller to produce non woven box bag aromatically.

|

Main Technical Variables |

||

|

Type |

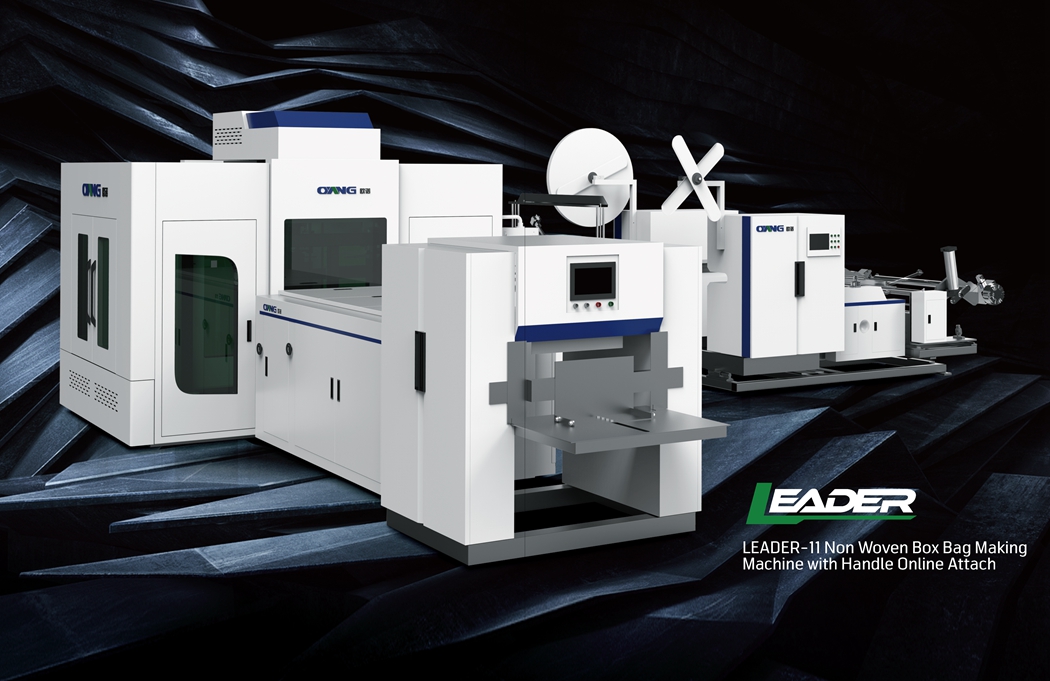

LEADER-11 |

|

|

Bag Capacity |

50-70 pcs/min |

Speed depends on bag size |

|

Bag Length |

180-500 mm |

|

|

Bag Height |

180-450 mm |

There is a one-to-one mapping between Bag Height and Bag Gusset |

|

Bag Gusset |

80-200 mm |

|

|

Power Supply |

Power Supply |

|

|

Total Power |

25KW |

|

|

Machine Size |

8500X6600X2600MM |

|

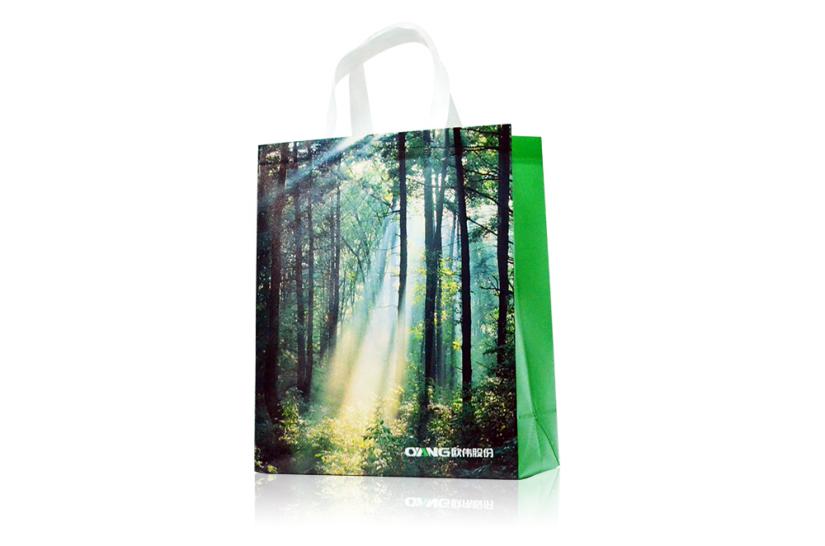

Bag Type - Leader can make

Non woven box bag

Lamination film thickness: 0.2 to 0.24 cm,

Non woven thickness: 90 grams per square meter ,

less than general weight cotton sails tarpaulins1/10 ,

but its vertical and horizontal tensile strength up to 30 kg can

be reached.

Long-term use in infrared, ultraviolet , laser and acid rain, snow or frost,

ecological or other physical and chemical environment.

PP non woven box bag

Non woven thickness: 90-120 grams per square meter.

Choosing traditional printing machine printing the non woven

fabric roll by roll before bag making.

Aluminum film non woven box bag

Composite materials

1. Plastic film coated with a thin layer of aluminum

2. non woven fabric

In a high vacuum state by high temperature the aluminum melt

evaporated and the vapor deposition of aluminum accumulated

on the surface of the plastic film so that the plastic film surface

with a metallic luster .

Glitter film non woven box bag

Composite materials

1. Glitter film with printing outside

2. non woven fabric

Glitter film suitable for offset printing, gravure printing ,

screen printing, special printing, stamping and other

processing methods.

It has been widely used in all walks of life on the packaging

industry decoration market

Embossing non woven bag

Composite materials:

1. One layer of BOPP Film, One layer of Non woven fabric

2. Double layer of non woven fabric

Processing way:

1. Hot stamping BOPP film

2. Laminated BOPP film with Non woven fabric

3. Embossing the laminated material.

4. Using Ounuo Leader to make the bag

PP woven bag

Composite materials:

1. One Layer of BOPP film, One layer of Woven fabric

Processing way:

1. Rotogravure printing BOPP film inside

2. Laminated BOPP film with Woven fabric

3. Using Allwell Leader to make the bag

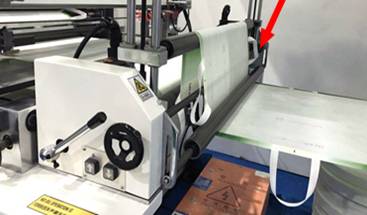

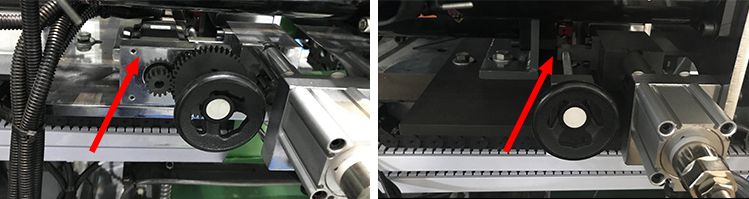

Photoelectric Eye For Correcting DeviationPhotoelectric Eye For Correcting Deviation

Automatic AdjustHand Wheel Adjust

|

|

Automatic AdjustHand Wheel Adjust

|

|

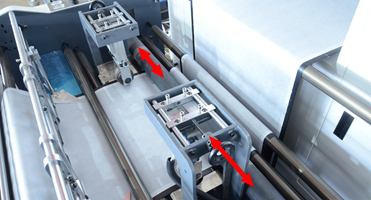

Online Creasing Device Position & Creasing DistanceOnline Creasing Device Position & Creasing Distance

Automatic AdjustHand Wheel Adjust

|

|

|

Automatic AdjustHand Wheel Adjust

|

|

|

Independent Ultrasonic Hot SealingUltrasonic Hot Sealing

Double Push DeviceSingle Push Device

|

Photoelectric Eye For Correcting Deviation Photoelectric Eye For CorrectingDeviationAutomatic Adjust

Handle Wheel Adjust

Allwell Supply More Intelligent Bag Making Machine ,

Save Your Time To Get More Advantage

|

Packing

|

|

|

Size

|

8500(L)*6600(W)*2600(D)

|

|

Weight |

12000KG |

|

Packaging Details

|

The normal package is plastic film with pearl cotton

|

Allwell Machinery, as a professional manufacturer of spunbonded PP non woven fabric line, non woven bag making machine, non woven printing machine, soft handle sealing machine and relevantequipment, has an area of 13,000 square meters and 130 on-the-job employees.

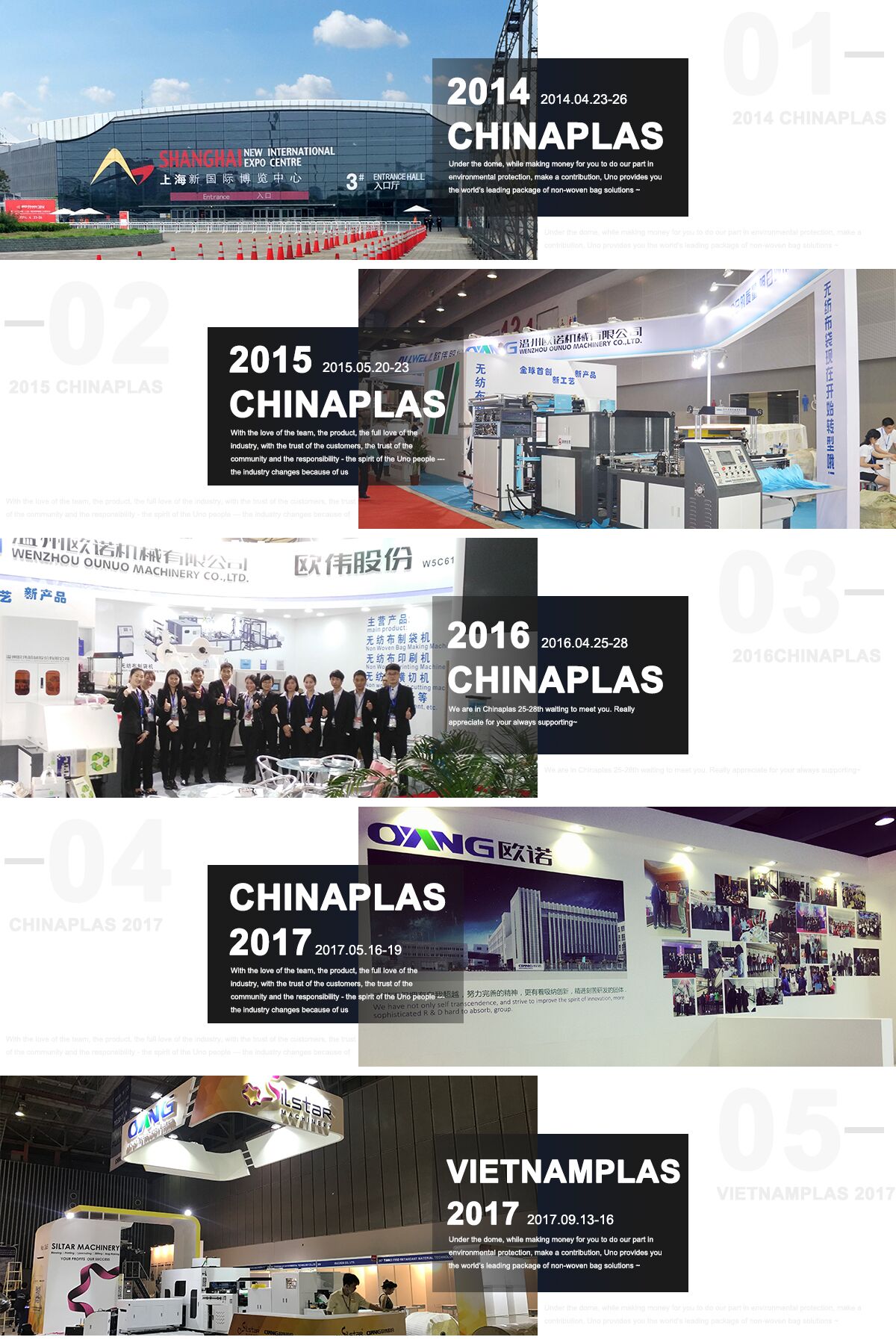

We start from a smart factory since 2006. We keep innovating and upgrading equipment to make non woven bag more attractive and durables. 2012-2013, we innovated the first set of one time forming laminated non woven box bag making machine all of the world and get successfully market. The products and services now cover more than 80 countries.

Today, we are adhearing energy saving, efficient, environmental idea to be the leader of non woven bag making industry. We have a great dream and responsibility to provide solution for the intelligent bag making industry.

Allwell have gained the certificate of ISO9001 quality management system with all products gained the European CE.

Our R&D Team merges the advanced philosophy to practice and succeeds in applying to the related products. The excellent quality and performance of our product originatedfrom our long-term and continuous test and improvement. 2012-2013, we setup a new project of one time forming non woven box bag making machine. We succeed developed this machine - Leader Machine and get the invention patents as shown above.

2015, we succeed build a new factory and 2016 we import 5 set CNC 5 sides work coordinate machining, 24 hours processing to guarantee the precision of the machine. All our products are better than therelevant industry standards.

Pre-Sales One-stop Service

* Inquiry and consulting support

* Latest industry trends

* More fit bag making solution

* Sample testing support

* View our Factory

* Suggest layout support

After-Sales Service

* One year warranty

* Machine test video before delivery

* English Manual, Electric Diagram

* Training how to install the machine, training how to use the machine

* Engineers available to service machinery overseas

- Bolso sénior no tejido haciendo consejero

- Nombre de contacto: Emy Tung

- Email: inquiry@allwell-group.com

- Teléfono móvil: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278