Product Application

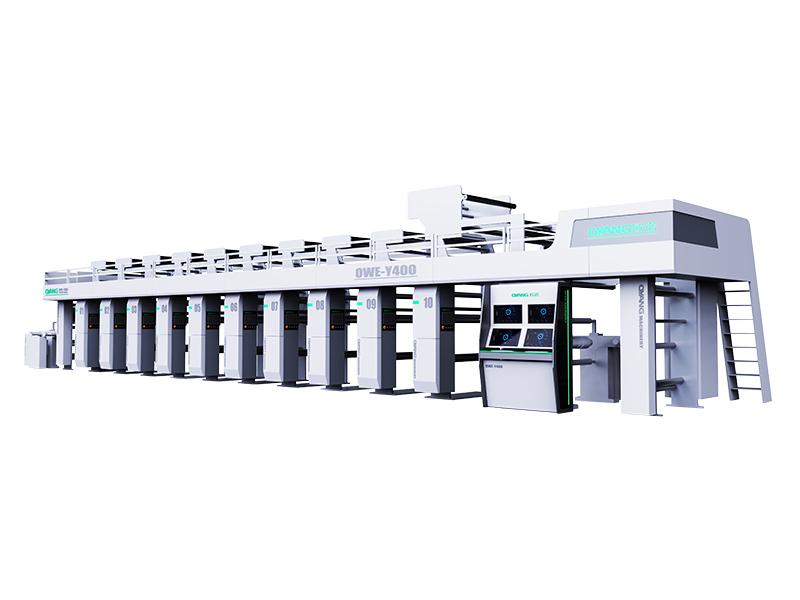

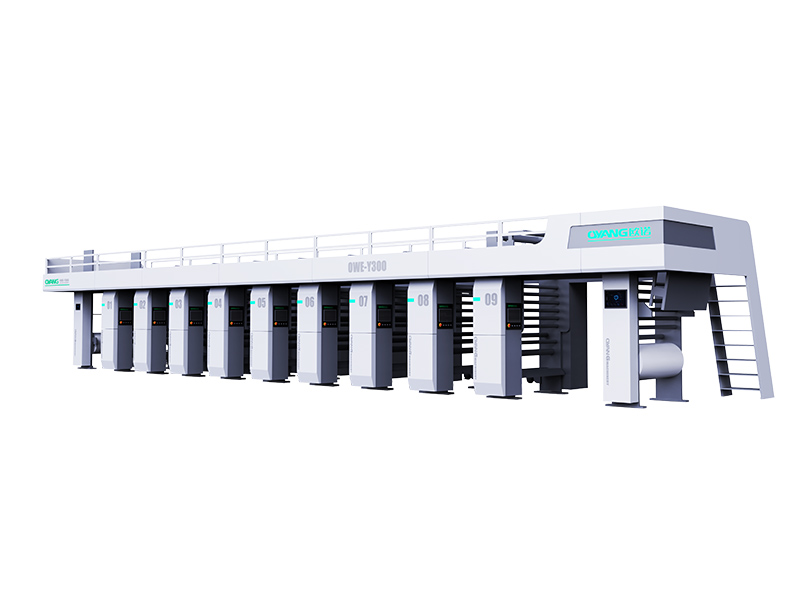

AZJ-81050A 8 Color Rotogravure Printing Machine

This machine is suitable for multi-color once-through continuous printing for such roll film materials with excellent printing performance asBopp film, pet, pvc, pe, aliminum foil, paper, etc.

|

Main Technical Variables |

|||

|

Type |

AZJ-81050A |

ONL-XB800 |

More Wide Can Be Customized |

|

Fabric Thickness |

35-100GSM |

35-100GSM |

More thin or thick tell us please |

|

Loop Handle Thickness |

60-120GSM |

60-120GSM |

|

|

Power supply |

220v 50Hz |

220V 50Hz |

Can change according your factory |

|

Total power |

18KW |

22KW |

|

|

Overall size |

12000X2600X2000MM |

12000X2700X2000MM |

|

|

|

|

BOPP Film |

Rotogravure Printing Sample |

|

Feeding Part

1. Rotate Rack in station wall,make sure the accuracy of Processes and installation |

|

Printing Unit (8 sets) 1. Separately station structure , easy for disassembling and installation

2. Plate cylinder is fixed by shaft-less air

chuck for plate cylinder changing high efficiency

|

|

|

|

Rewinding Part

1. Rotate Rack in station wall,make sure the accuracy of Processes and installation.

|

|

The following is OUR load container info for AZJ-81050A Rotogravure Printing Machine. Special data would be supply after confirm your order.

|

|

|

Container

|

One 40'ft container

|

|

Weight |

21000KG |

|

Packaging Details

|

Dust proof package

|

Allwell Machinery, as a professional manufacturer of spunbonded PP non woven fabric line, non woven bag making machine, non woven printing machine, soft handle sealing machine and relevantequipment, has an area of 13,000 square meters and 130 on-the-job employees.

We start from a smart factory since 2006. We keep innovating and upgrading equipment to make non woven bag more attractive and durables. 2012-2013, we innovated the first set of one time forming laminated non woven box bag making machine all of the world and get successfully market. The products and services now cover more than 80 countries.

Today, we are adhearing energy saving, efficient, environmental idea to be the leader of non woven bag making industry. We have a great dream and responsibility to provide solution for the intelligent bag making industry.

Allwell have gained the certificate of ISO9001 quality management system with all products gained the European CE.

Our R&D Team merges the advanced philosophy to practice and succeeds in applying to the related products. The excellent quality and performance of our product originatedfrom our long-term and continuous test and improvement. 2012-2013, we setup a new project of one time forming non woven box bag making machine. We succeed developed this machine - Leader Machine and get the invention patents as shown above.

2015, we succeed build a new factory and 2016 we import 5 set CNC 5 sides work coordinate machining, 24 hours processing to guarantee the precision of the machine. All our products are better than therelevant industry standards.

Pre-Sales One-stop Service

* Inquiry and consulting support

* Latest industry trends

* More fit bag making solution

* Sample testing support

* View our Factory

* Suggest layout support

After-Sales Service

* One year warranty

* Machine test video before delivery

* English Manual, Electric Diagram

* Training how to install the machine, training how to use the machine

* Engineers available to service machinery overseas

- Packing project conserlor

- Contact Name: Emy Tung

- E-mail: inquiry@allwell-group.com

- Mobile Phone: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278