Product Application

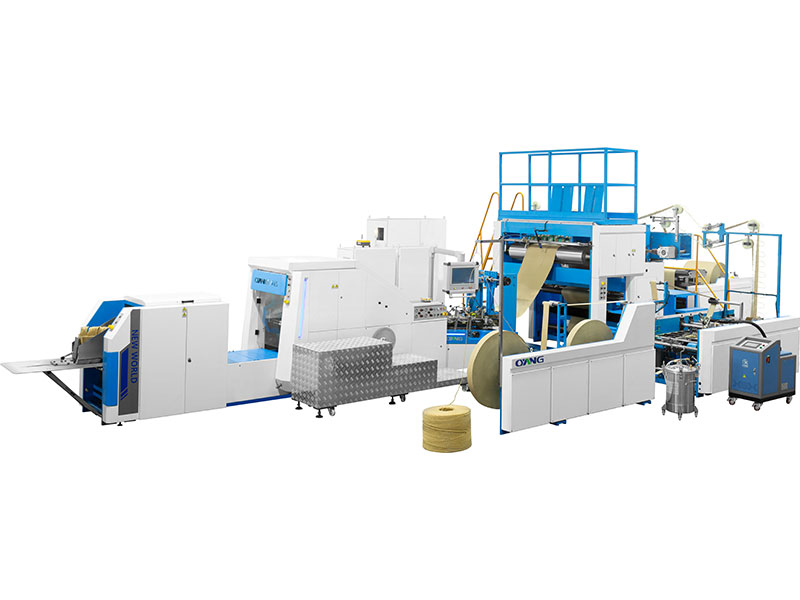

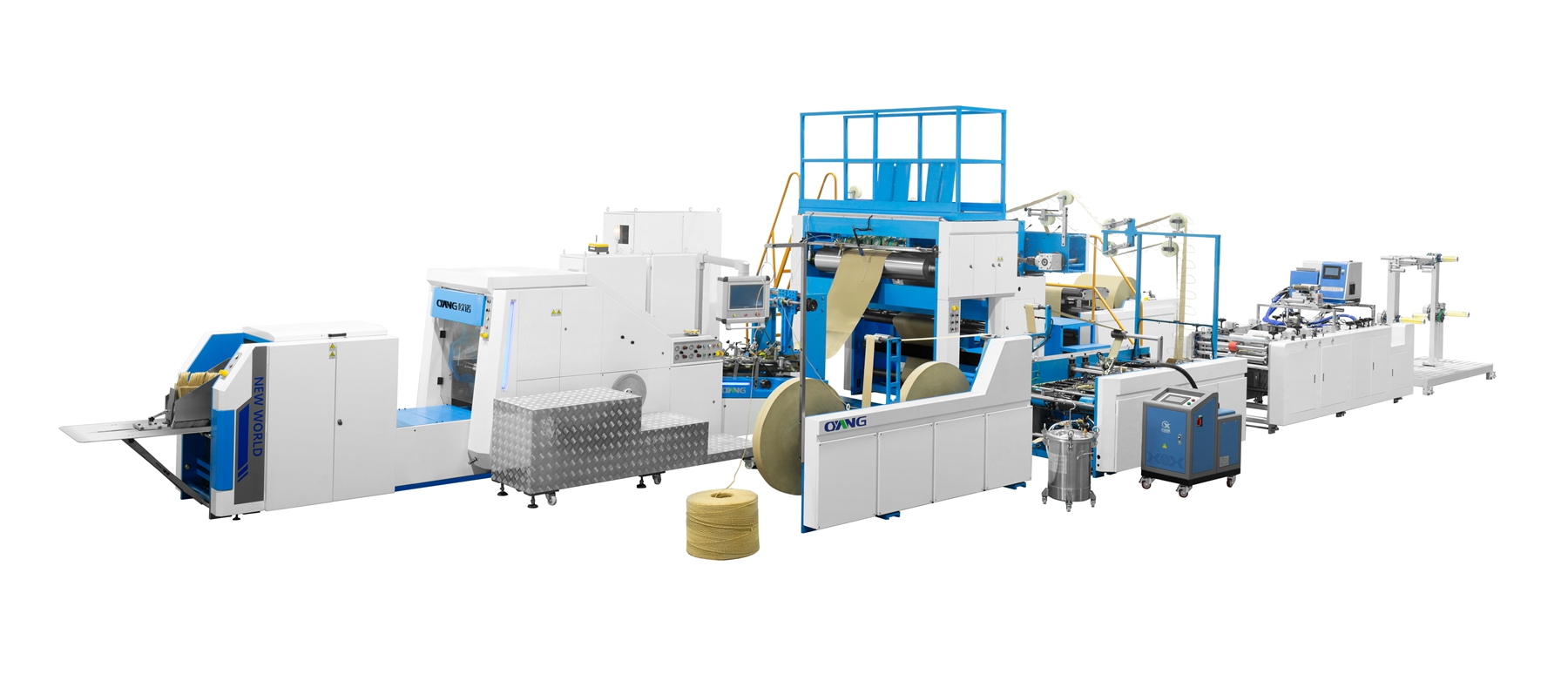

Fully automatic square bottom paper bag machine is used for the production of a paper bag with a twisted handle loop. Transmission of the handle made by handle making unit, cut, stick, pressed, and then pre-cut, glue, auto handle stick in empty or printed roll paper. Then the main machine will glue the paper with the handle loop to the edge, paper bag tube forming, cut off, indentation, bottom glue, bottom forming, and sealing, bag conveying. the whole process is completed simultaneously at one time. Real realization of full automation production, can effectively save labor costs.

The whole machine adopts the servo-electric control system imported from Japan, which ensures the whole machine can run quickly and stably and effectively reduces the time of paper bag size adjustment. The finished bags produced are of high accuracy, strong stability, simple maintenance, and efficient production, which is the ideal equipment for major printing plants and paper bag manufacturers.

Main Technical Variables

| Model | New World-A220 | New World-A330 | New World-A400 | New World-A450 | New World-A460 | New World-A560 |

| Paper Diameter | ≤1500mm | ≤1500mm | ≤1500mm | ≤1500mm | ≤1500mm | ≤1500mm |

| Core Inner Diameter | ∅76mm | ∅76mm | ∅76mm | ∅76mm | ∅76mm | ∅76mm |

| Paper Weight | 70-140gsm | 80-140gsm | 80-140gsm | 80-140gsm | 80-140gsm | 90-140gsm |

| Paper Bag Width | 120-220mm with handle | 200-330mm with handle | 200-400mm with handle | 200-450mm with handle | 240-460mm with handle | 280-560mm with handle |

| 80-220mm without handle | 150-330mm without handle | 150-400mm without handle | 150-450mm without handle | 220-460mm without handle | 280-560mm without handle | |

| Paper Tube Length | 191-350mm with handle | 280-430mm with handle | 280-550mm with handle | 280-550mm with handle | 320-650mm with handle | 320-650mm with handle |

| 191-430mm without handle | 280-510mm without handle | 280-600mm without handle | 280-600mm without handle | 320-770mm without handle | 320-770mm without handle | |

| Bottom Width Of Paper Bag | 50-120mm | 80-180mm | 90-200mm | 90-200mm | 90-260mm | 90-260mm |

| Paper roll width | 290/370-710mm | 490/590-1050mm | 510/610-1230mm | 510/610-1230mm | 650/690-1470mm | 770-1670mm |

| Machine Speed | 150pcs/min | 150pcs/min | 150pcs/min | 150pcs/min | 130pcs/min | 100pcs/min |

| Total Power | 32kw | 32kw | 34kw | 34kw | 34kw | 34kw |

| Machine Weight | 13000kgs | 16000kgs | 18000kgs | 18000kgs | 21000kgs | 22000kgs |

| Machine Dimensions | 12000X5000X2500mm | 14000X6000X2500mm | 15000X6000X2500mm | 15000X6000X2500mm | 16000X6000X3500mm | 16000X6000X3500mm |

Bag Type - New World-A series can make

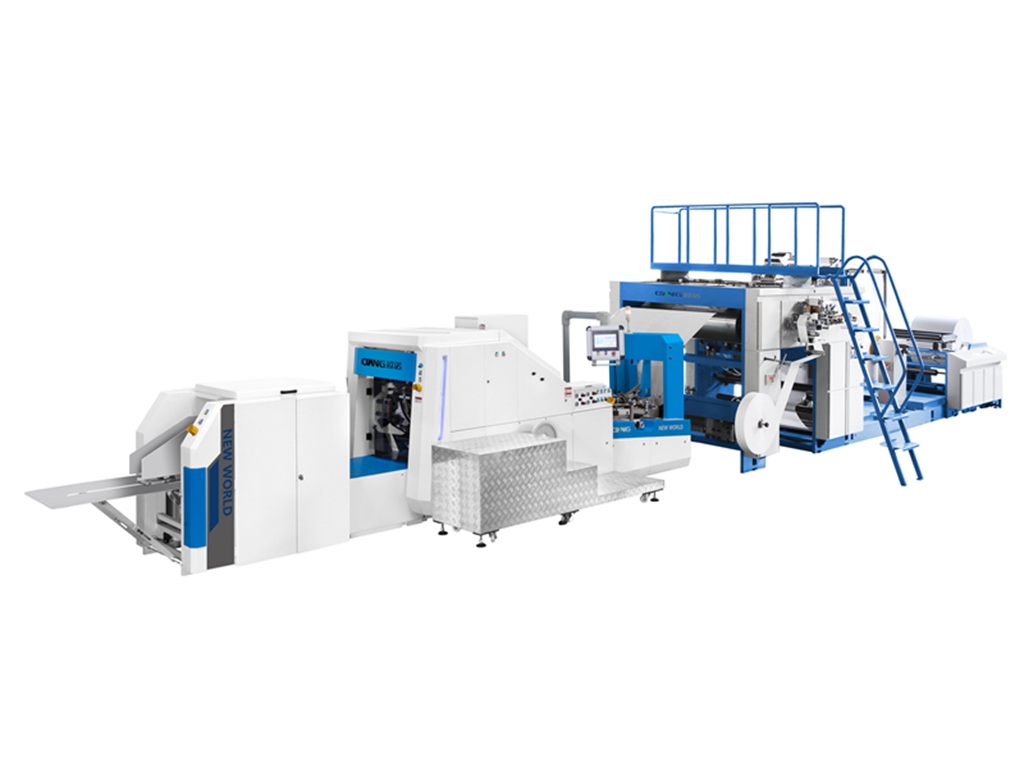

Full Machine Servo Motor Structure

Our new technology full servo control paper bag machine,it is equipped with lip cut servo,cutting knife servo,bag opening servo,bottom gluing

servo,bottom closing servo,bag collection servo and main servo,more intelligent for customer running.

Advantages:

1.Reduce time when adjusting bag size.

2.More capacity for production.

3.Low requirements for engineers operation experience.

4.More intelligent.

Ouyang brand paper bag making machine,high speed, low noise,energy-saving.

Main wallboard: The raw material is nodular cast iron, which made by pouring molten iron. More force and wear resistance, high strength, high toughness, stable running and machine life extended by up to 80 %.

Big hub: Integral casting , 5-axis machining, perfectly curved surface, finished in 10 hours continually work, minimize fitting errors.

Former support: The former support is to held the big hub,so it should be strong enough for high speed and long time running.

Developing fast and covering an area of 130,000㎡。

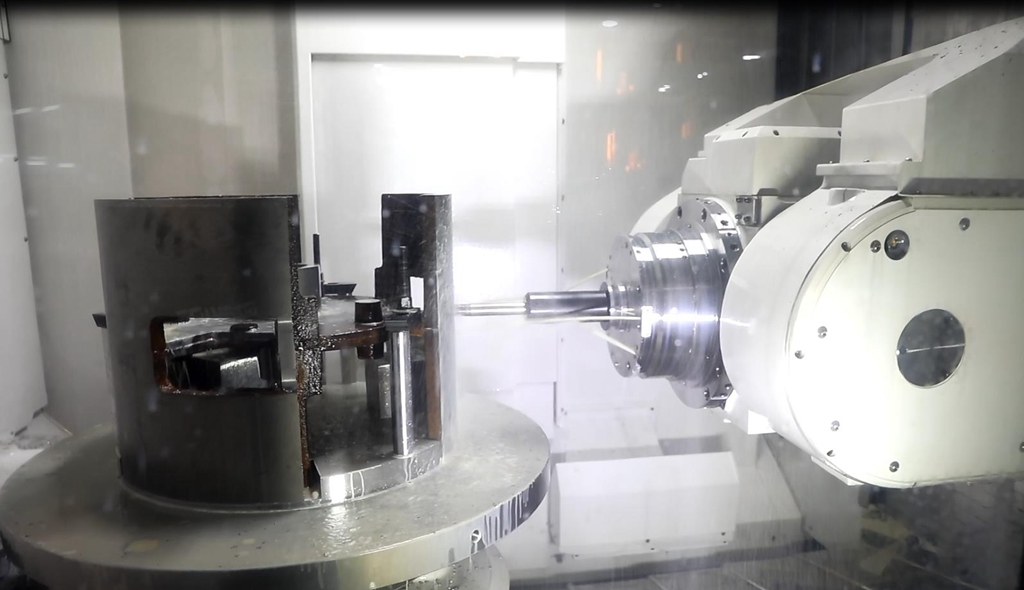

MAZAK HCN6800L FLEXIBLE PRODUCTION LINE (6 SETS)

MAZAK HCN6000L FLEXIBLE PRODUCTION LINE( 6 SETS)

Mazak Horizontal Machining Center. The maximum capacity of the tool magazine is 330 tools, which can meet the requirements of workpiece diversification and unmanned production.

MAZAK VCN700DL ( 1SET)

Mazak vertical machining center. Agile spindle acceleration and deceleration, high-speed axis feed, and efficient tool exchange effectively shorten the processing time.

MAZAK QTC200MYL ( 2SETS)

MAZAK QTC300MYL ( 2SETS)

Third, Mazak CNC lathe. Using the latest SMOOTH G system, it can be widely used in aerospace, instrumentation and other industries. High-efficiency machining requirements for small precision parts.

Mazak i-630v/6 ( 1SET)

Fourth, Mazak 5-axis simultaneous vertical machining center. The equipment is equipped with a swing spindle and a rotary table, which can perform 5-axis simultaneous machining of complex surfaces.

Okuma MCR-A5II25 (4SETS)

Fifth, OKUMA-MCR gantry type 5-sided machining center. Equipped with various extended processing systems to complete 5-sided, curved and other three-dimensional processing, the roughing and finishing of almost all processes can be completed in one clamping.

- Packing project conserlor

- Contact Name: Emy Tung

- E-mail: inquiry@allwell-group.com

- Mobile Phone: +8613567711278

- WeChat: 13567711278

- WhatsApp: +8613567711278